This is the 10th blog in our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. See part 1, part 2, part 3, part 4, blog 5, blog 6, blog 7, blog 8, and blog 9.

Today we are continuing our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. We’ve looked at numerous ISO standardized test methods for a variety of properties, and today we are looking at the stability test method.

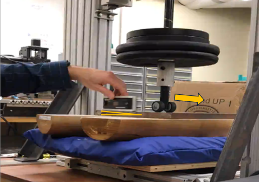

With the seating standards, we’re not only concerned with tissue integrity, we’re also concerned with the positioning and stability of the person on the cushion and in the wheelchair. There is a new ISO draft, ISO 16840-13, that is being developed specifically to measure lateral stability. This method uses the same indenter as several of the other standards, representing a seated body. The indenter is centered and leveled on the cushion, weight is applied to the center of the indenter, then a portion of the load is shifted to the side, simulating a lateral reach, for example. The amount the cushion tips in response to this shift is measured in degrees of tilt, giving an indication of how a cushion might react to a person leaning or reaching to the side. Would they be stable and held in place, or would the cushion perhaps move too much and be a cause for concern for stability? Again, we cannot draw exact conclusions, since the stability test method is a simulation in a laboratory environment and not a real-world measure of a person’s movement. However, this mechanical, scientific approach allows us to compare cushion technologies for an idea of how they may perform, in comparison to other cushions.

The NPIAP/EPUAP/PPPIP clinical practice guidelines provide numerous considerations when choosing support surfaces. A wheelchair cushion needs to be acceptable for the individual, it must minimize pressure and shear, and it should provide adequate support. Providing a stable support surface is key to ensuring the individual can perform their full range of motions and activities.

Let’s take a closer look at the test fixture at the University of Pittsburgh. You can see how the indenter is initially loaded with weight in the center and leveled. The load is shifted to the right, and the resulting angle is measured.

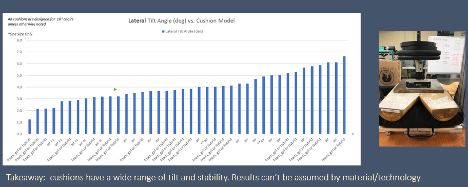

The data returned can look like the chart below. Each of the bars represents an individual cushion, and their height indicates how far the cushion tilted as a result of the load shift. All things are equal as much as possible following the draft of the ISO standard.

The data gives you some indication of which cushions might be more stable than others. These objective tools can also help you compare categories of materials, and whether the general type of material is indicative of a level stability, or whether the more complicated specific materials, design, and construction contribute to the performance. In this case, when cushions are categorized broadly by “foam, gel, or hybrid”, for example, results are scattered across the full range, from the most stable at just over 1 degree of tilt, up to the greatest amount of tilt at about 6 ½ degrees. The data reinforces that we can’t just think about a particular material being more appropriate for stability. Every cushion is different, and every manufacturer has a different design intent and approach. This same range of results can be found with air cushions in this chart—some air cushions demonstrate high stability, while others are much less stable. The takeaway is that different cushions demonstrate a wide range of tilt and stability, and results can’t be assumed by material or technology.

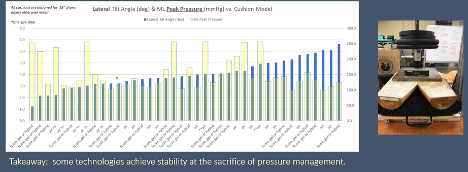

An additional layer of analysis was performed with this collection of cushions. The testing was repeated with pressure mapping to understand how the stability was achieved, and whether there was any potential compromise to pressure management, while in the tilt position. The graph below includes the original tilt data. The peak pressures measured during the lean are represented by the overlaid yellow bars.

Two of the cushions that were the most stable, on the left side of the graph, had the lowest amount of tilt but the highest peak pressures. That is the mechanism by which they were achieving their stability – the cushions were pushing back, resulting in these peaks. The 3rd cushion from the left was still very stable and maintained a low peak pressure, so this cushion looks like a “best of both worlds” option. When a quick lean is performed, and the person returns to center, this may not be critical, however, with clients who cannot reposition themselves and find themselves leaning for a long period of time, this may be more critical. Again, not every cushion is right for every person, but if you know what is key to the client, data such as this can help direct you to potential solutions.

Join us next week for a final blog and recap of this series.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.