Editor's note: This post was originally published in February 2020 and has been updated for accuracy and comprehensiveness.

This is the 4th blog in our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. Interested in seeing how Permobil uses science and evidence to support our innovations? Check out our Trust & Transparency page. See part 1, part 2, part 3, part 4, blog 5, and blog 6.

We’re continuing our blog series focused on Understanding Cushion Properties with the Help of ANSI/RESNA and ISO Standards. Today’s blog takes a closer look at the ISO standard 16840-6 of simulation of aging standard and the pressure mapping test method.

![]()

Pressure, shear, and microclimate are the key characteristics called out in the clinical practice guideline in the definition of pressure injuries. There are standards that address these factors.

Pressure Mapping Test Method

Pressure Mapping is one of the tests applied to characterize the cushion. If you work in wheelchair seating, pressure mapping is a tool you’re most familiar with. One of the main goals when considering a wheelchair cushion is to provide pressure redistribution. There are limitations to pressure mapping systems as the mat itself can interfere with how the cushion interacts with the seated individual, limiting the true immersion into the cushion cover and materials. It also, of course, does not give information about how the internal tissues may be affected. Pressure mapping can, however, give some cursory information in the clinic, when different solutions are being considered, as a limited tool in the process of clinical reasoning. Simply looking at data provided by different manufacturers becomes tricky, as it might not be clear how the cushion was set up when the data was obtained, how the person was positioned on the cushion or in their wheelchair, what their body types and needs were, and so on. To reduce these sources of variability, pressure mapping becomes a more useful tool when it is in a laboratory setting under an ISO standard.

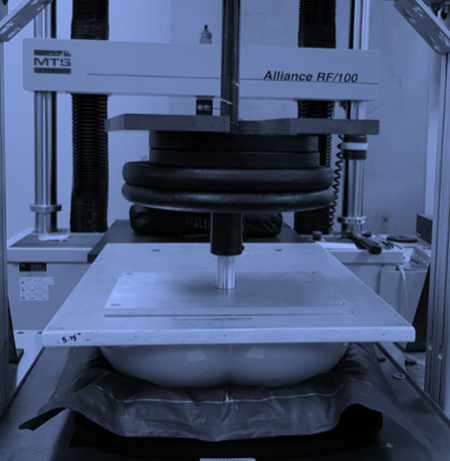

Bench testing under controlled conditions can start to minimize the variables. A physical form was created that’s shaped like the buttocks and is rigid. Since this “indenter” is rigid, it doesn’t reproduce a human body, but it does give a standardized shape, size, and stiffness that a standardized weight can be applied to, as part of the full scientific testing protocol. This means the tests are repeatable, and data can be compared if you want to evaluate the effect of changing cushions or covers, or if a cushion designer wants to evaluate different materials and constructions to see what the effects are and whether or not performance may be improved. This standardization gives you an apples-to-apples comparison. When you have controlled the variables, you get a clearer view of what may be different across different technologies and different cushion solutions. Again, the ISO standard methods don’t indicate pass or fail, but the test results can help narrow choices you might want to consider for your individual.

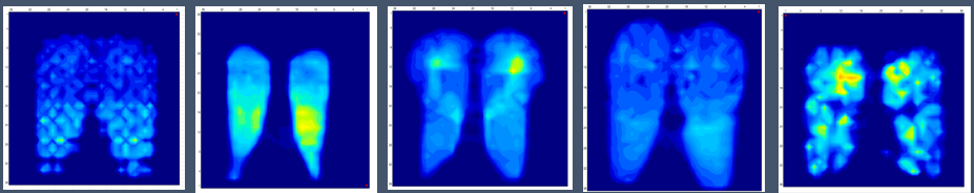

Let’s look at some examples obtained from the University of Pittsburgh using the ISO standard 16840-6 method for pressure mapping under the controlled conditions in their Tissue Integrity Management Laboratory. A very general takeaway is that even though these are different cushions classified or promoted as “skin protection cushions” they demonstrate different contact areas, different peak pressures and different average pressures. The examples provide insightful information for the clinical decision-making process, depending on the individual’s needs.

Join us next time as we continue looking at the different test methods within the ISO 16840-2 standard and look closer at the immersion test method.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.