This is the 9th blog in our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. See part 1, part 2, part 3, part 4, blog 5, blog 6, blog 7, and blog 8.

We are nearing the end of our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. We’ve looked at numerous ISO standardized test methods for a variety of properties, and today we are looking at the envelopment test method.

ISO 16840-12 is the envelopment standard. We previously discussed the importance of measuring immersion, since the ability of a cushion to immerse the body and support the pelvis is a key characteristic for managing pressure. While immersion is important, it only tells us how deeply the body potentially sinks into the cushion - it doesn’t tell us how well the cushion fits to the body to fully support it. Just from the standpoint of basic physics, we want to maximize the contact and support between the body and the cushion, to reduce the pressure as much as possible. This is referred to as envelopment. Pressure mapping gives us some idea of envelopment, by measuring contact area, but the pressure mat itself is somewhat rigid and prevents a true picture of envelopment from emerging.

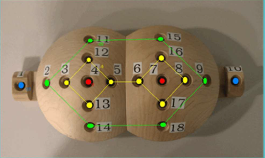

To remove the effect of the pressure mat, the ISO standards committee developed a curved apparatus which is meant to reproduce the shape of the buttocks. The surface has numerous holes, which you can see in the image below, which house small sensors that take direct pressure readings, without a separate, interfering pressure mat. Since the sensors are located at different points along the curved surface, the data gives a better indication of how the load is supported across the curvatures. By looking at this collection of data, we have an idea of how the forces of the body are managed by the cushion, and whether the cushion evenly distributes the load in the pelvic area, or partially or fully offloads. Additionally, the sensors are precise, laboratory grade components, which can provide more reliable data than traditional pressure mapping systems.

The CPG for pressure injury prevention talks about cushion construction achieving pressure redistribution by either immersion/envelopment or redirection/offloading. Once again, the ISO standards provide an objective, laboratory bench test for evaluating the ability of a cushion to achieve these goals.

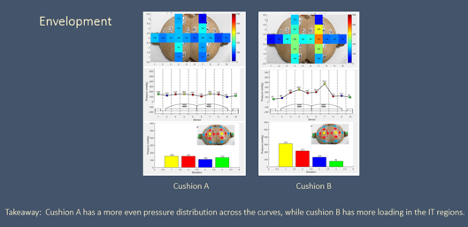

With this test, you can look at two different cushions, for example, and see how they manage load differently. The data is a little complicated, but in the charts below, the line graphs with the colored dots represents the pressures that are read across the center line of the indenter from the left GT across the ITs to the right GT. Those values are similar for Cushion A, so that surface is fairly evenly supporting the body across this centerline, the same centerline used in the immersion test. Cushion B has peak pressures at both ITs, with one being even higher than the other. That’s important to understand since the ITs are vulnerable to pressure injury, and peak pressures should be avoided here. This is new information that is not revealed by the immersion test alone.

The colored bar charts – yellow, red, blue, and green, represent the average of the sensors in the colored zones mapped in the indenter above. These values further demonstrate that Cushion A is distributing the load across the entire curved surface somewhat evenly, while cushion B is loading the region around the ITs the most, followed by the ITs themselves.

It’s useful to have this objective data for further insight to what’s potentially happening when someone is seated on a cushion.

Join us next week for our last blog in the series.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.