Editor's note: This post was originally published in February 2020 and has been updated for accuracy and comprehensiveness.

This is the first of our blog series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. See part 1, part 2, part 3, part 4, blog 5, and blog 6.

Permobil has always believed in the science and evidence when designing and testing products, especially for seating and positioning wheelchair cushions.

As we return to our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards, let’s start with an overview of the standards process. The international standards, the ISO standards, are developed globally by a broad group of participants with a variety of experiences including technical experts, clinicians, and end users from a number of countries. The ISO standards started over a hundred years ago with that essential question: what’s the best way to do something? The standards apply to everything from footwear to building materials to children’s toys and so on. There are over 20,000 standards that are currently published by over 240 technical committees, with one hundred standards created each month. The goal of the technical committees is to look at not only products but also services with an eye towards ensuring safety, quality, reliability, and especially in the case of medical devices, effectiveness.

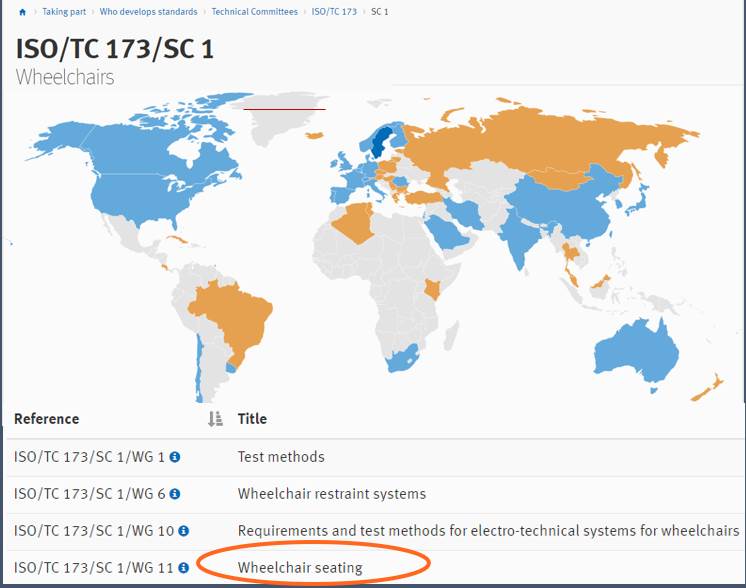

Specific to us, wheelchair seating falls under an assistive product technical committee. Within that committee, there is a specific subcommittee for wheelchairs. The map below shows the participation from around the world—a broad input of perspectives goes into creating these standards.

The specific working group for wheelchair seating meets three times a year around the world, working toward full input and consensus as the documents are developed and published. The process is very lengthy, starting with the idea of a test that might be needed to provide understanding about how a wheelchair cushion works. A tremendous amount of engineering and testing goes into the process. Extensive input and review is needed to make sure the test methods are not only appropriate, but are also reasonable for a test lab or a manufacturer to be able to apply.

Another consideration is whether the tests are meaningful for the end user—are the results important? Just because a physical property can be measured doesn’t mean it is worth investing time and energy in the testing. By holding these meetings around the world, different perspectives are constantly weighing in on these important questions, refining the draft standards, adding data for analysis, and ensuring the most appropriate draft standards are proposed. These drafts then undergo multiple international comment periods and votes, ensuring the final, published standards have been vetted and refined.

Join us next week as we chat more about the benefits and limitations of standards in the next blog post. Also, check out the Permobil Trust & Transparency page that includes information on how our cushions performed under ISO testing.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.