Editor's note: This post was originally published in February 2020 and has been updated for accuracy and comprehensiveness.

This is the 5th blog in our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. See part 1, part 2, part 3, part 4, blog 5, and blog 6. Interested in seeing how Permobil uses science and evidence to support our innovations? Check out our Trust & Transparency page.

We’re continuing our series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. If you haven't been following along with this series, be sure to check out the links above to catch up. Last week we looked at the ISO 16840-6 standard of Pressure Mapping Test Method. Today we’re looking at the Immersion Test Method, which is part of both ISO 16840-6 and ISO 16840-2.

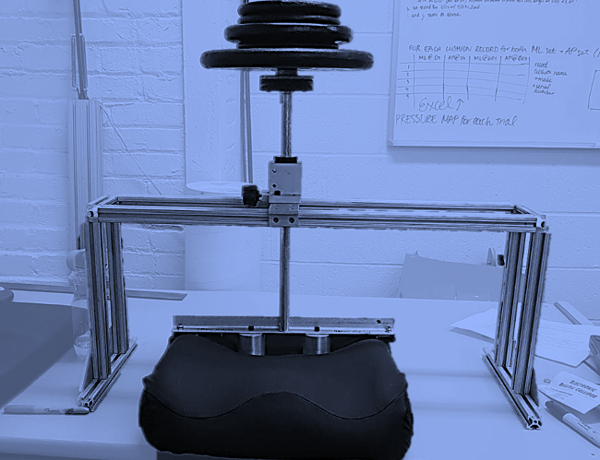

ISO 16840-2 has numerous test methods specifically for characterizing cushions that are intended to provide tissue protection. The depth of immersion tells us if the cushion really is deep enough to support the pelvis. The illustration below shows the indenter used for the test. This mechanical representation of the body has two large cylinders in the center, simulating the ischial tuberosities (ITs), and two cylinders on the edges, simulating the greater trochanters (GTs). The four cylinders are scaled to represent a typical pelvic structure. This analog is loaded with weights and pushed into the cushion, allowing for measurement and assessment of whether the cushion can potentially support the full pelvis, not just the ITs, without “bottoming out.”

The NPIAP/EPUAP/PPPIA Clinical Practice Guideline on the Prevention and Treatment of Pressure Injuries (CPG) notes that cushion construction achieves pressure redistribution in two methods: immersion and envelopment or redirection and offloading. The depth of immersion and contour is typically 40-45mm (1.6-1.7”) for most individuals. This value was a design input to the indenter, which can allow for an objective measure of this critical cushion property, in a lab, under the controlled conditions specified by the ISO protocol.

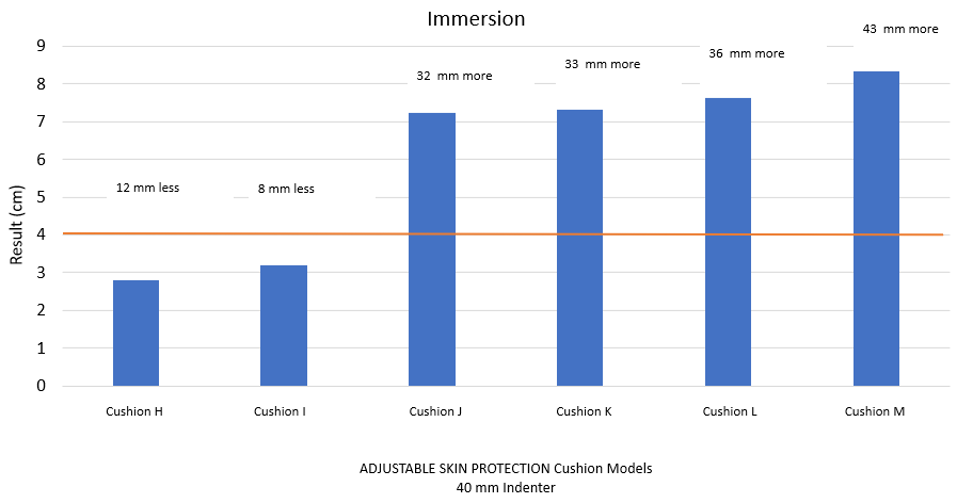

The U.S. Centers for Medicare and Medicaid Services recognized the value of the immersion test, and adopted a slightly modified version of the ANSI/RESNA and ISO method as a requirement for cushions to be coded as reimbursable medical devices. In this regulatory application, there are firm pass/fail limits. Cushions coded as “general use” must pass the immersion test with a 25 mm indenter, and those coded as “skin protection” must pass with the 40 mm indenter.

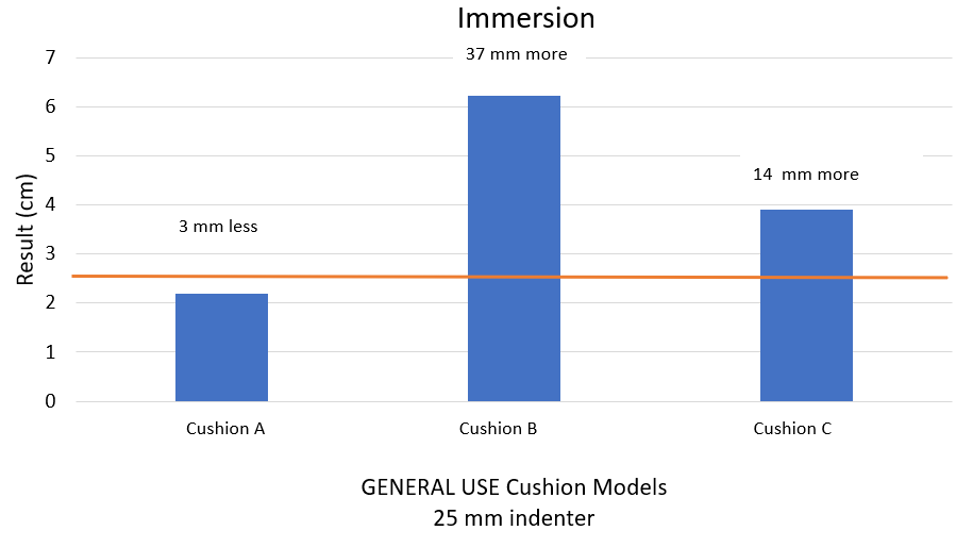

As noted in the CPG, you can find a wide variety of support surface choices in the market, and their characteristics and performance can vary. For example, the graph below demonstrates the test results of three different cushions evaluated by the University of Pittsburgh, all of which are considered general use cushions. The immersion depths varied greatly, and one of them would not meet the US coding requirement.

Significant variation in immersion is also observed across cushions that are considered to be “skin protection” models. Again, not all cushions with these claims would meet the US coding requirements.

Both of these graphs remind us that not all cushions perform in the same way. While there is not a single standardized test that determines which cushion is the right fit for the client, the immersion test is of particular interest, since it:

- is tied to the CPG recommendations for support surfaces,

- was designed based on pelvic dimensions cited in the CPG and the broader medical literature,

- has been adopted by the US as a pass/fail for qualification for reimbursement

New data and cushion performance metrics have been completed with a wide range of cushions from various manufacturers. Check out the results and look closer as to why one ISO standard result should not be utilized as a cushion selector tool.

Join us next week as we look further within the ISO 16840-2 standard and discuss horizontal force and shear tests.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.