Editor's note: This post was originally published in February 2020 and has been updated for accuracy and comprehensiveness.

This is the 2nd in our blog series on understanding cushion properties with the help of ANSI/RESNA and ISO standards. See part 1, part 2, part 3, part 4, blog 5, and blog 6.

Recently we took a look at how ISO and RESNA standards operate and the overall goal of these standards as they apply to wheelchair seating. As we continue on our journey through understanding cushion properties with the help of ANSI/RESNA and ISO standards, today we’re discussing the benefits and limitations of standards.

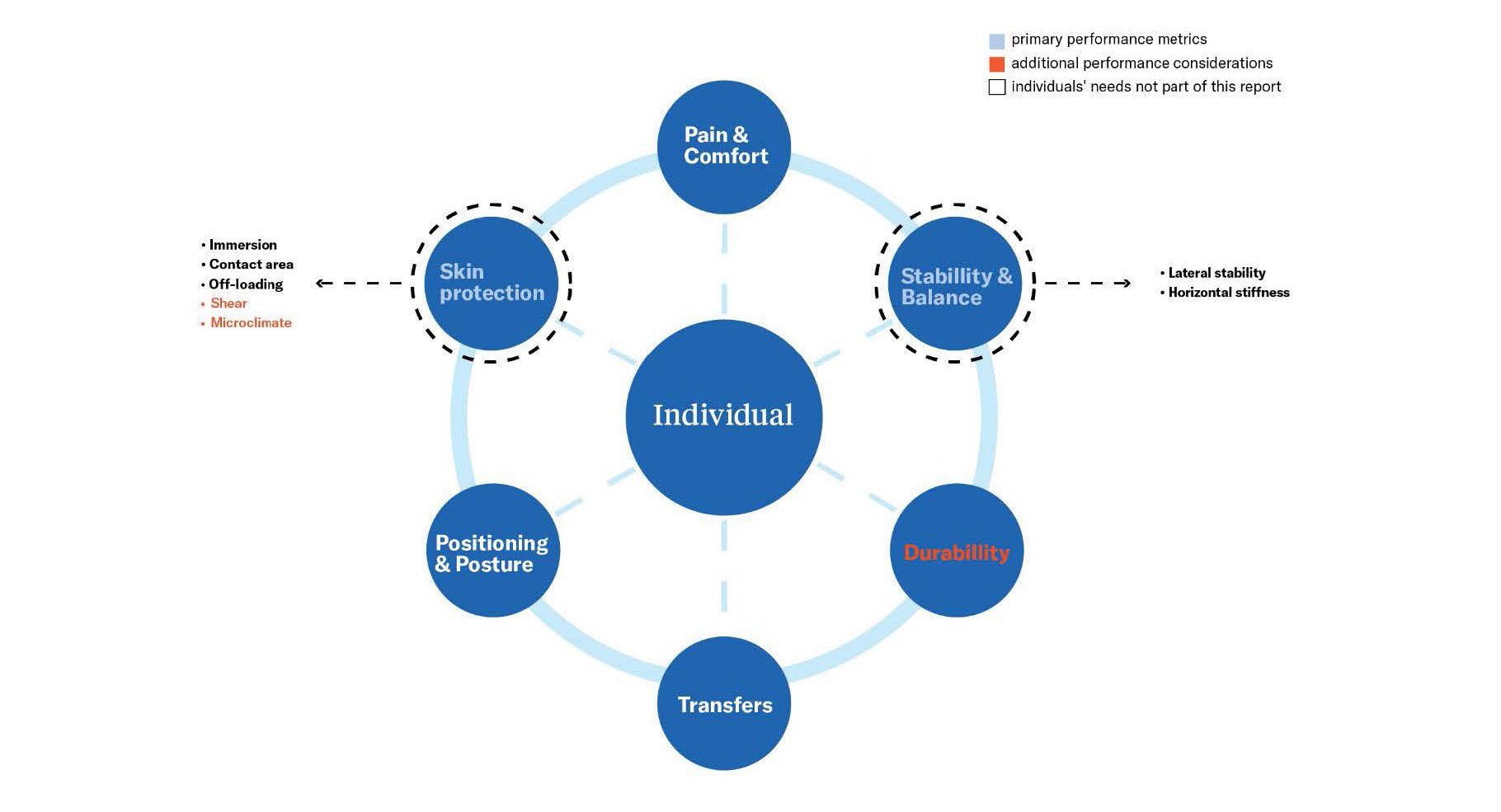

There are numerous benefits to having standards and there are some limitations as well. The standards are developed to be tests that can be performed under controlled laboratory conditions. The goal is to be able to measure those key product characteristics in a scientific, repeatable way, so we can get meaningful information allowing you to compare properties and solutions objectively. It also encourages innovation. Having an understanding of what is critical for a wheelchair cushion, we can think about better ways to enhance those properties that we’re looking for. Overall, by having properties developed and tested to an international standard, consumers and clinicians can have increased confidence in the suitability of that solution.

A limitation of standards is they are not intended to endorse specific solutions, they just allow for direct comparison of specific properties which have been identified by the standards committees as being critical. This allows for apples-to-apples comparison of solutions, to better understand how they may perform and potentially meet the client’s needs. The benefit of this performance based approach is that it allows the manufacturers to continue to innovate, developing new materials and techniques that give the measurable properties the client is seeking. Permobil had the opportunity to have cushions selected for ISO testing as part of a larger research project, and the results can be found here.

Standards don’t typically have pass/fail boundaries. For many of these tests, we know the properties that are critical, but since an individual is so unique and has such specific and inherent risks, challenges, or needs, it’s difficult to have fixed properties assigned to be a solution for every person. Typically, the standards are used to help you compare and contrast the performance characteristics a client is looking for.

Lastly, it’s important to note the standards and testing are not at all intended to replace clinical reasoning. Standards are meant to be additional tools that can be used in the decision-making process for the individual.

Join us next time as we discuss how standards relate to clinical practice.

For more information on the CPG, ANSI/RESNA Wheelchair and Related Seating Standards Committee, and the ISO standards for Wheelchairs and Wheelchair Seating, please visit:

https://guidelinesales.com/page/Guidelines

https://www.resna.org/AT-Standards/Wheelchair-and-Related-Seating-WRS

https://www.iso.org/committee/53792/x/catalogue/p/0/u/1/w/0/d/0

Images provided by the University of Pittsburgh Tissue Integrity Management Laboratory

Kara Kopplin, B.Sc.Eng,

Kara Kopplin, B.Sc.Eng,

Chair of the ANSI/RESNA Wheelchair and Related Seating Committee, Director of Regulatory Science for Permobil

Kara Kopplin holds a B.Sc. in Ceramic Engineering from the University of Missouri-Rolla, U.S.A., bringing a unique and complementary materials engineering perspective to seating solutions. In her role as Director of Regulatory Science for Permobil, Inc., Ms. Kopplin actively contributes to the efforts of the International Organization for Standardization (ISO) and European Committee for Standardization (CEN) to develop object test methods for wheelchair systems and components. She is honored to chair the ANSI/RESNA Standards Committee on Wheelchair and Related Seating (WRS) in the US and encourages everyone to contribute to the development of these critical evaluation tools.