Empowering consumers by allowing them the freedom to choose their manual wheelchair (MWC) frame material allows them the ability to utilize a device that best fits their physical, personal, and healthcare needs. It allows them to choose a material that not only enhances their function but allows the personal assurance that they were an active participant in the choice! A consumer’s right to choose is a hot topic and The Choices for Increased Mobility Act of 2023 (H.R. 5371) aims to amend title XVII of the Social Security Act to clarify payment rules for MWCs under part B of the Medicare program. On December 6th, 2023, the committee assigned to this bill recognized it for further consideration by the House or Senate. For further details, feel free to explore our previous blog post on this topic.

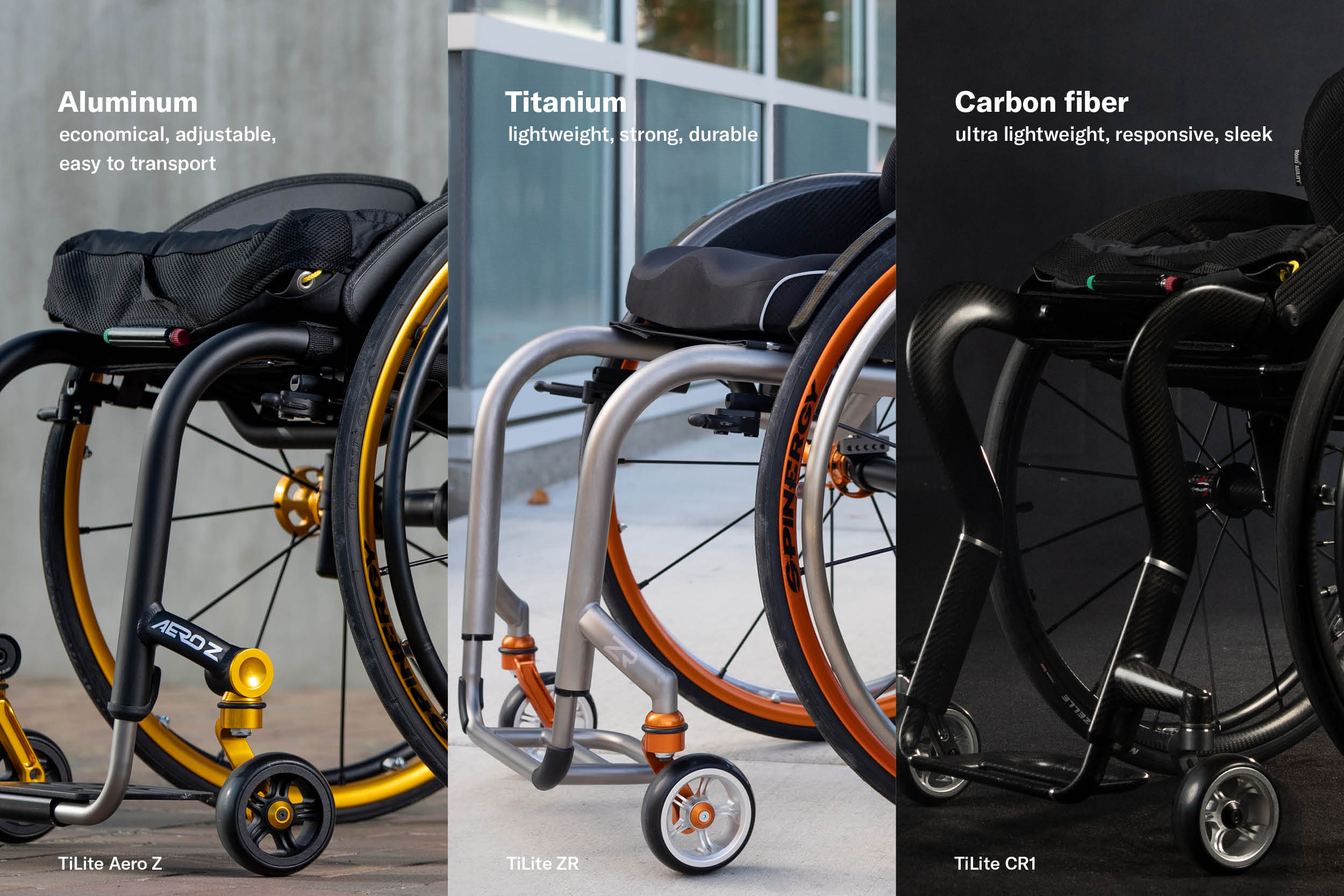

Thoughtful selection of the materials used to manufacture an ultralight weight MWC is critical to ensure the MWC is not only functional but also durable, safe, and suitable for the consumer. Understanding the characteristics of the materials used will help the consumer decide which material to choose. Today, ultralight manual wheelchairs are typically made with aluminum, titanium, or carbon fiber. Why would a consumer choose one over another?

Why aluminum?

Aluminum is the most common and cost-effective material used by manufacturers to make ultralight weight MWCs for many reasons. They are lightweight, corrosion resistant, “funding friendly,” and customizable. Aluminum is significantly lighter than other metals like steel which makes it easier for consumers to propel their wheelchairs. Aluminum provides the necessary structural integrity for wheelchair frames without adding excessive weight. It has a natural oxide layer that protects it from corrosion, which is advantageous for outdoor use. Aluminum can be easily shaped and welded, allowing for a customized design and the ability for manufacturers to tailor the frame to the exact measurements and dimensions of the individual. Aluminum frames can be anodized or coated in various colors, enhancing the appearance, and allowing for individual expression.

Why titanium?

Wheelchairs have been made of titanium for over 20 years. The benefits of titanium as a material are numerous: extremely high strength to weight ratio, corrosion resistance, lightweight, durability and configurability. Chairs made from titanium have a wider variety of configurability options available. These options may enable a consumer to be more functional or match the chair's shape to the rider's body. Active consumers may benefit more from a titanium chair due to the durability of the chair; or because raw/unpainted titanium looks quite nice to some people, the frame of an unpainted titanium chair ages quite well as many scuffs and scratches can easily be buffed out.

Consumers never have to worry about a titanium wheelchair looking worn from the inevitable chipping of paint from normal daily use. The manual wheelchair world borrows technologies from the bicycling world. And many people love a titanium bike because of the “ride quality” over the much stiffer ride of an aluminum bike. People who have had titanium wheelchairs may experience the same ride quality impressions.

Why carbon fiber?

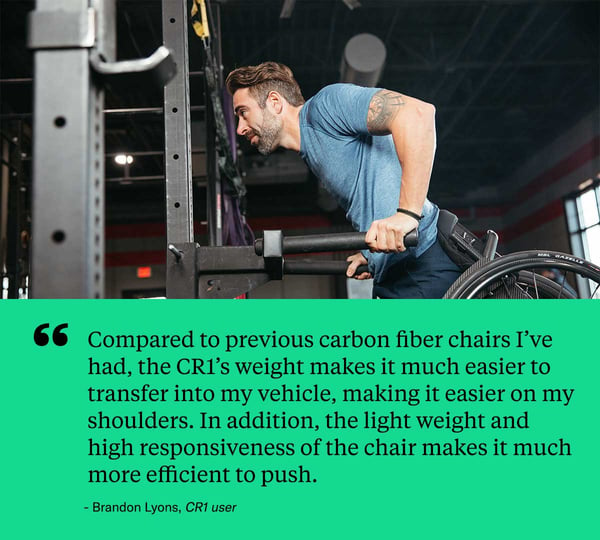

If a consumer needs a chair that will be the lightest and easiest to propel, they need to look no further than carbon fiber. Chairs made from carbon fiber are woven together in a particular pattern for a specific load purpose. The result is a MWC that not only looks sleek but also is incredibly lightweight and efficient. A recent study showed that chairs made from carbon fiber had a higher fatigue factor than aluminum and titanium. This indicates that if a consumer handles their chair with care, the frame will last an incredibly long time. This may add value to the higher initial cost, as the chairs may last longer.

When working with carbon fiber, the wheelchair manufacturer is not limited to the shape and bending constraints of a metal tube. Carbon fiber can be shaped; woven in a myriad of ways to enhance the look and resultant effect of the chair. These factors allow consumers who choose carbon fiber wheelchairs to choose a chair that will not only last a long time, protect their shoulders, but also fit their lifestyle.

Funding for titanium and carbon fiber

Again, aluminum is the most commonly prescribed mainly because it is the “funding friendly” option, but if an individual needs titanium or carbon fiber the process is different. Currently, there are two ways in which DME suppliers may file claims: “assigned”, which means that the Medicare allowable is accepted as payment in full and “non-assigned,” in which the supplier collects their usual and customary charge up front from the beneficiary, files the claim, and then the beneficiary is reimbursed less their co-pay and applicable deductible. Non-participating suppliers may file non-assigned claims if the Medicare allowable for an item is not sufficient based on the cost of providing the item.

Thomas Halka, MOT, OTR, ATP

Regional Clinical Education Manager

Thomas Halka, MOT, OTR, ATP is an occupational therapist and is a Clinical Education Manager for Permobil, supporting Texas, Louisiana, Arkansas and Oklahoma. Thomas joined the Permobil in 2019. Prior to this, he practiced at the Dallas VA Medical Center in Spinal Cord Injury Unit. Here he provided complex seating and mobility solutions for veterans with SCI/D and multiple sclerosis. Thomas earned his ATP from RESNA in 2018, is a member of AOTA, and has served Texas Woman’s University School of Occupational Therapy as a member of the Vanderkooi Endowed Lectureship advisory council. Thomas resides in Dallas, TX with his wife, 3 kids and 2 dogs.

Leslie Wade, MOT, OTR/L, ATP

Regional Clinical Education Manager

Leslie Wade, MOT, OTR/L, ATP is an Occupational Therapist and a Regional Clinical Education Manager for Permobil. Leslie joined Permobil in February of 2019. Prior to this, she received her Masters of Occupational Therapy from Virginia Commonwealth University in 2002 and practiced occupational therapy as a full-time clinician for people with spinal cord injuries. Through this she has learned the invaluable need for proper seating & positioning and mobility devices. In addition to providing education in her territory, she also teaches at local PT/OT programs. Leslie served as the VCU Health Safe Patient Handling and Mobility Champion. This opportunity provided her with extensive experience in program development, education, and mentoring.